Reliable protection for night vision systems

Maximum transmission and durability for clear vision in total darkness

Characteristics

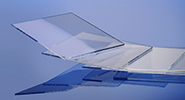

A central element of these devices is the optical protective cover – the so-called coverglass. It protects the sensitive sensors inside from environmental influences, mechanical stress and contamination. At the same time, it must not impair the visual performance of the system.

Your advantages

What are night vision and thermal imaging devices?

Night vision devices are mostly based on either:

- Image intensifiers – they require minimal ambient light and typically operate in wavelength ranges 400–1100 nm

- Active IR technology – uses infrared emitters in ranges 780–1100 nm whose reflection is detected by objects.

B 270® is ideal for high optical performance oriented applications, including many modern multispectral systems combine visible images with thermal sensors – where B 270® can be integrated as a protective window or front glass.

Why is protective glass crucial in night vision?

The cover glass must meet several requirements:

- High transmission in range 400-1100 nm

- Guarantee low absorption

- Be mechanically resilient and have high scratch and impact resistance

- Resistance to UV, moisture and thermal shock

- Compatibility with anti-reflective, IR or hydrophobic coatings

B 270®: The optimal glass solution for night vision systems

B 270® is a super-white crown glass with excellent transmission up to approx. 2500 nm. It combines optical performance with high mechanical and temperate resistance, making it ideal for devices that work with Image intensifiers and Active IR technology in the 400-1100 nm range – such as surveillance cameras, target optics or driver assistance systems.Advantages at a glance

Technical details

Technical details

SCHOTT B 270® glass offers excellent luminous transmission (up to 92% at 2 mm thickness), making it an ideal material for cover glass in night vision systems. Its excellent transmission in the 400–1100 nm range ensures that light passes through with minimal loss, enabling bright, high-contrast imaging.

| Property |

B 270® | PMMA (Acrylic) | Optical Glass |

|---|---|---|---|

| Transmission (400–1100 nm) |

~91–92% | ~88–89% | ~91–93% |

| Scratch resistance | High | Low | High |

| Tempering | Very good | Not possible | Very good |

| Optical homogeneity | Very high | Very low | Medium |

| Availability in required thicknesses | High | Limited | Low |

| Slimming/polishing effort | Low | High | High |

| Price-performance ratio | ++++ | ++ | ++ |

| Advantage |

Effect on B 270® |

|---|---|

| Scratch resistance | Protection against sand, dust and cleaning |

| Temperature stability | No distortion in cold or warm environments |

| Weather resistance | No yellowing or fogging during extended outdoor deployment |

| Coatability | Ideal for AR or hydrophobic coatings |

| Durability | Longevity even with intensive use |

B 270® offers a very good basis for functional coatings:

- Anti-reflection coatings (AR) to reduce reflections

- Hydrophobic coatings for outdoor or military applications

- Heating layers (e.g. TCO) to prevent fogging in the event of temperature differences

Fire polished surface with roughness ≤ 1 nm is ideal for certain coatings depending on type. The high adhesion and mechanical stability of the glass ensure a long service life of the coatings, even under load or temperature shifts.

| Thicknesses | ||

|---|---|---|

| 0.80 mm |

2.00 mm | 2.80 mm |

| 0.90 mm |

2.10 mm | 3.00 mm |

| 1.00 mm | 2.15 mm | 3.15 mm |

| 1.10 mm | 2.20 mm | 3.30 mm |

| 1.15 mm |

2.25 mm | 3.50 mm |

| 1.20 mm | 2.30 mm | 4.00 mm |

| 1.35 mm | 2.40 mm | 4.50 mm |

| 1.50 mm | 2.50 mm | 5.00 mm |

| 1.65 mm | 2.65 mm | 5.50 mm |

| 1.70 mm | 2.70 mm |

6.00 mm |

| 1.85 mm | 2.75 mm | |

*Other thicknesses available on request.