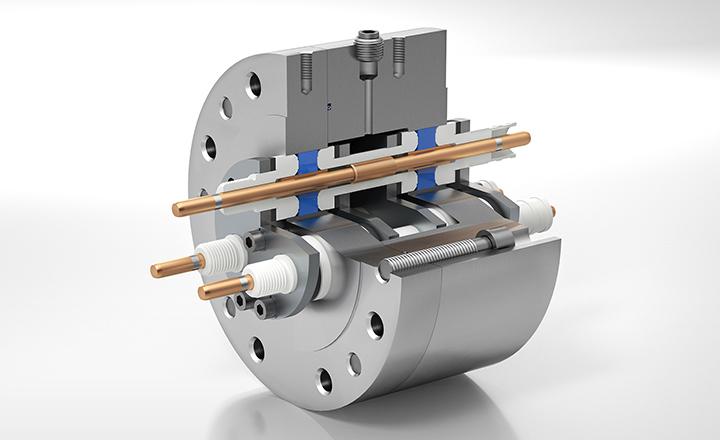

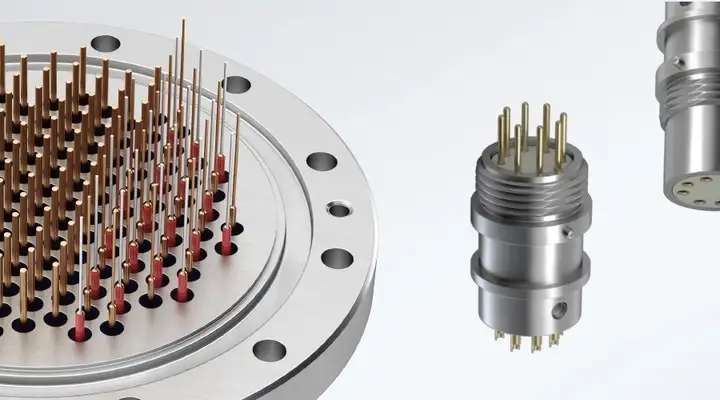

Eternaloc®

Superior robustness and performance for challenging energy applications

Eternaloc® feedthroughs represent a proven worldwide standard for the transmission of electrical power and data in a variety of safety-critical, harsh-environment applications. The components simultaneously act as gas diffusion-proof isolation elements.

Explore product properties in detail

Christian Rakobrandt

Sales Manager