Glass optical fibers: Properties, applications, manufacturing

Types of glass used

There are several types of glass used in fiber optics:

- High-purity silica: This glass provides exceptional optical clarity and low attenuation. It has a numerical aperture of about 0.2. Therefore, it is especially suitable for applications such as telecommunication.

- Doped silica: Compared to high-purity silicia, it enhances the refractive index for specialized applications. The numerical aperture is usually between 0.37 and 0.39. Typical applications include fiber optic measurement systems.

- Multi-component glass such as borosilicate glass: This type has the highest numerical aperture of the three. Light guides made of multi-component glass offer an acceptance angle of up to 120 degrees, while image guides can achieve acceptance angles of up to 180 degrees and a numerical aperture of 1. It is customizable for specific performance and cost requirements and is mainly used for lighting and imaging applications.

Understanding the properties and applications of glass optical fibers

Glass fibers are highly flexible and unaffected by a range of environmental factors, such as chemical exposure, high and low temperatures or pressure. Additionally, they offer no risk of electrical interference. The unique characteristics of these fibers make them essential for developing reliable and efficient systems in challenging environments – for instance, decoupling electronic devices such as light sources, sensors or cameras from the actual area of application.How do glass optical fibers work?

Light transmission

Light guides carry light from one end to the other. The arrangement of SCHOTT’s fibers can be randomized to create very homogenous illumination.

Single-mode vs. multi-mode fibers

Single-mode fiber

Single-mode fibers have a small core (< 10 µm) and a large cladding. As a result, only one light ray is transmitted, which leads to low loss and only minor scattering. Those fibers are usually preferred for long distance datacom.

Key properties and advantages of glass optical fibers

Thanks to their technical properties, glass optical fibers offer numerous advantages over other materials. This makes glass optical fibers indispensable in modern technological applications.

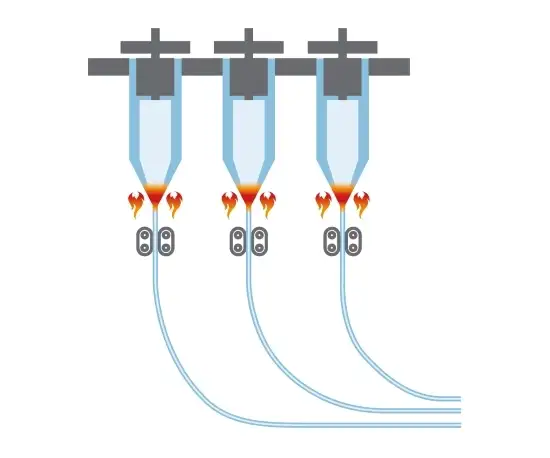

Why are optical fibers made of glass flexible?

By heating glass rods, it is possible to draw glass fibers that are about as thin as a human hair. The speed of the drawing process determines the fiber thickness, which in turn determines the flexibility of the fiber. The smaller the fiber diameter, the smaller the bending radius. In this respect, fibers made of specialty glass are even more pliable and flexible than plastic fibers.

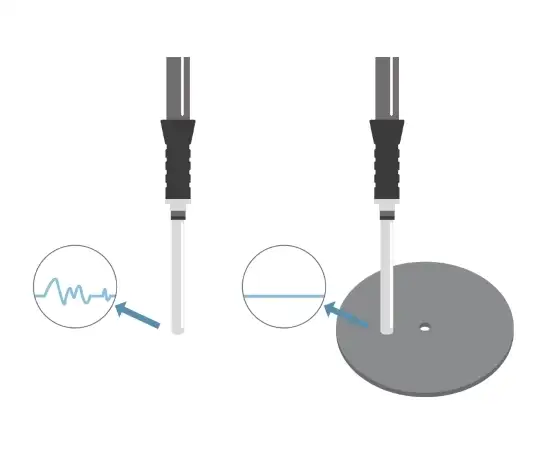

The breaking loop test is used to test the flexibility of glass fibers. This is performed by placing a flexible glass fiber in a loop, which is pulled tighter until the fiber breaks. This test has shown that for example glass fibers with a thickness of 50 micrometers can withstand a bending radius of about five millimeters.

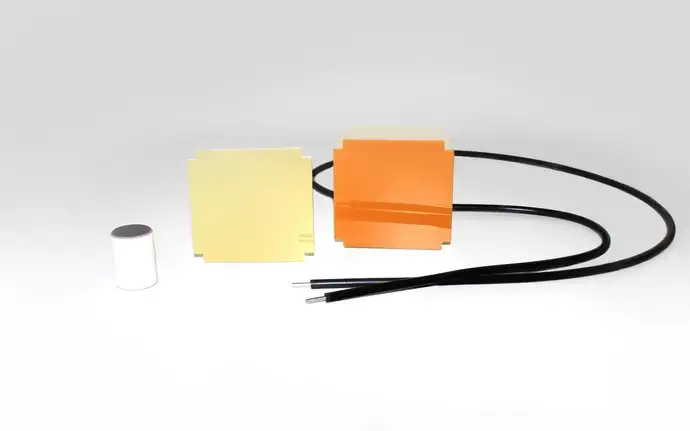

Types of fiber optic guides

Glass optical fibers can be made into flexible and rigid products, usually referred to as guides or cables. Flexible fiber optic cables are often longer than rigid ones and normally used when the inspection target lies around a corner or in a narrow, hard-to-reach space. This demands a high level of flexibility and movement, required for example in flexible endoscopes.

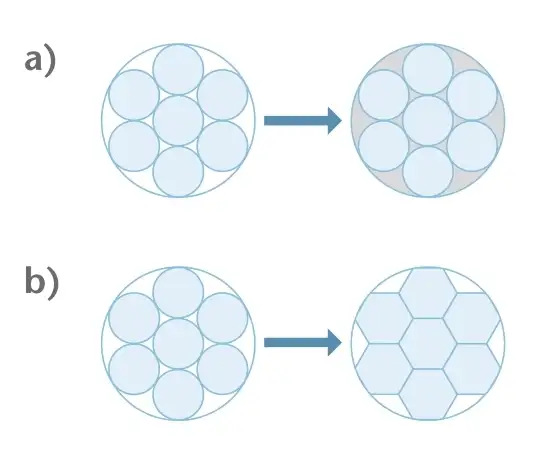

Rigid light or image guides are made up of bundles of fused fibers. Typical lighting applications include light guides for dentistry equipment or rigid endoscopes. For imaging applications, they are used to make a wide range of tapers and faceplates, which can transmit magnified, reduced or inverted images from an input surface to an output surface. To give an example from the medical field: faceplates are used in x-ray imaging. Hybrid variants are also available.

Glass optical fiber cables: How they are made

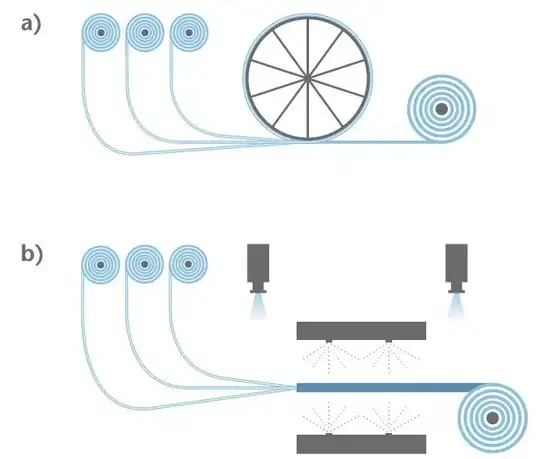

Fiber drawing

Precision bundling and extrusion

a) Precision bundling

Several primary bundles are gathered to form a final fiber bundle, with the fiber arrangement within flexible bundles usually arbitrary. For certain applications it may be necessary to arrange the fibers in a randomized pattern (light guide) or specific pattern (image guide).

b) Extrusion

The final fiber bundle has the option to be sheathed with polymer in an extrusion line to form a cable. In subsequent assembly processes, fiber bundles and cables are cut to length according to customer requirements and fitted with end sleeves.

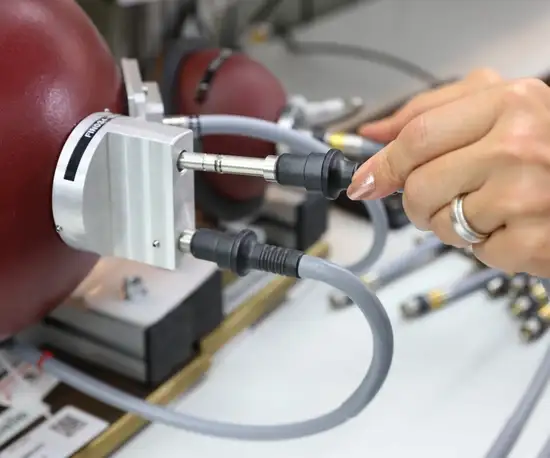

End termination

Redrawing and reshaping

Grinding and polishing

Quality inspection

Why are optical fibers made of glass?

Optical fibers are made of glass because of its exceptional optical properties, including high clarity and low attenuation. Glass fibers provide reliable and efficient light transmission, essential for critical applications in medical, industrial, aviation, automotive and defense. In addition, glass offers exceptional mechanical, thermal, and chemical properties, making them well suited for use in harsh environments.

Glass vs. plastic in optical fibers

While both materials have specific uses, glass optical fibers are superior for high-performance applications. They offer lower attenuation, higher bandwidth, and better environmental resistance compared to plastic fiber optics.

1. Superior light performance

Glass optical fibers, foundational for both flexible and rigid light guides, deliver a very high light transmission performance. The high color rendering index of glass ensures minimal wavelength alteration of the light entering and exiting the fiber. Glass fibers also boast a large numerical aperture of up to 1, allowing more light to pass through and illuminating larger areas with smaller fiber bundles. Conversely, polymer optical fibers are limited by material constraints to a maximum aperture of 0.5.

2. Strength and flexibility

Glass fibers combine exceptional strength with flexibility when reduced to very thin diameters. This unique combination allows glass fibers to be manufactured as thin as 30 microns, enabling tight bending radii. In contrast, polymer fibers typically have diameters starting at 500 microns, often exceeding 1 mm. For imaging applications, individual glass fibers can be as small as 4 microns in diameter, providing high pixel resolution and detailed, clear images.

3. Thermal stability

Glass maintains stability at temperatures up to 350 °C, making glass fiber bundles or rigid light guides suitable for high temperature application like autoclaving sterilization in medical applications or hostile industrial environments. Polymer fibers, however, generally withstand temperatures only up to 80 °C, making them unsuitable for such high-temperature processes.

4. Design flexibility

The extremely small diameters of glass fibers allow a high number of individual fibers to fit into a compact bundle, facilitating complex geometries in small spaces. Glass fiber bundles can also distribute light from a single source to multiple locations efficiently, mixing red, green, and blue LED light to produce homogeneous white light. The higher number of glass fibers in a bundle results in a more uniform light output compared to thicker polymer fibers.

5. Chemical resistance

Glass’s high chemical resistance ensures it remains inert when exposed to cleaning agents, detergents, acids, bases, solvents, or glues, making glass components durable and easy to clean. In contrast, polymers can react with various chemicals.Why SCHOTT?

With over 130 years of experience, SCHOTT is the world’s leading expert in optical glass. Our knowledge, innovation and attention to detail ensure that no matter what your industry and requirement, we will give you our full support in finding the right solution.