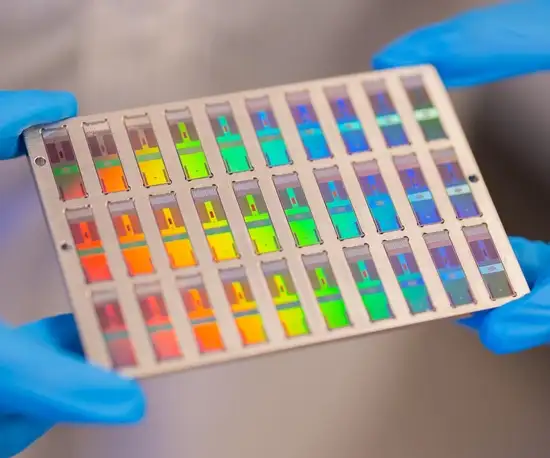

SCHOTT® Microarray product variants

Glass microarrays

Materials

Depending on the assay and type of array (DNA or protein) a different functional coating may be required to complement the molecule adherence.

Your advantages

There are many advantages to printing on glass including:

- High-quality optical glass allows for scanning through the glass with minimal impedence, and therefore increased optical transmission. With high-quality, flat glass and fewer defects experienced compared with other materials, the transparency allows scanning from all sides for optimal signal quantification.

- Glass has lower auto-florescence in comparison to other materials such as nitrocellulose and many polymers, eliminating interference with signal quantification.

- Glass is more cost-effective as an alternate to silicon for cingulated point-of-care device production.

Polymer / plastic microarrays

Materials

Common materials used for printing polymer microarrays include: COP, COC, polypropylene, acrylic.

Your advantages

The main advantage of polymer-based microarrays is cost-effectiveness, particularly in the production of high-volumes of polymer substrates through injection molding to reduce overall product COGs.

Silicon microarrays

Materials

We print on silicon die, packaged chips and wafers to enable optimal detection in both labeled and unlabeled molecular assay platforms.

Your advantages

The use of silicon as a substrate allows for many types of detection beyond standard fluorescence, such as electrical detection, differential mass determination, and ion quantification. The unique properties of silicon enable:

- Complex and accurate sensor pad definition and the ability to make unique sensor pad format layouts.

- Electrical detection for signal read outs and electrically driven on-chip control of temperature including on-chip PCR cycling.

- Intricate on-chip microfluidics to drive assay flow.

Would you like to learn more about SCHOTT® Microarray materials? Let’s talk!

Accelerate your vision and get to market faster!