Technical Details of FOTURAN® II

Homogenous, versatile and precise

Available products

SCHOTT FOTURAN® II is available as:

- Polished substrates and wafers

To find out more, please see the related products on the overview page.

Structuring process and characteristics

Working principle

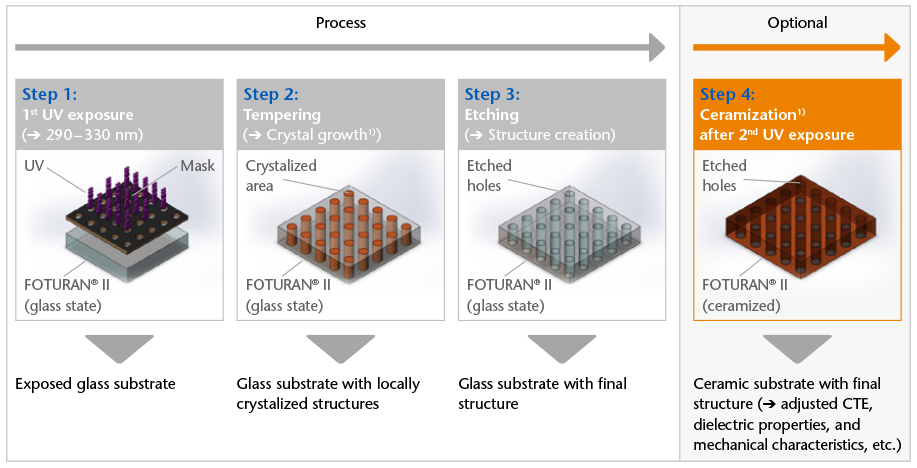

FOTURAN® II is a photo-structurable glass-ceramic and structured in three steps – Ceramization as a 4th step is optional

1) Different temperature profiles during crystallization lead to different crystal structures

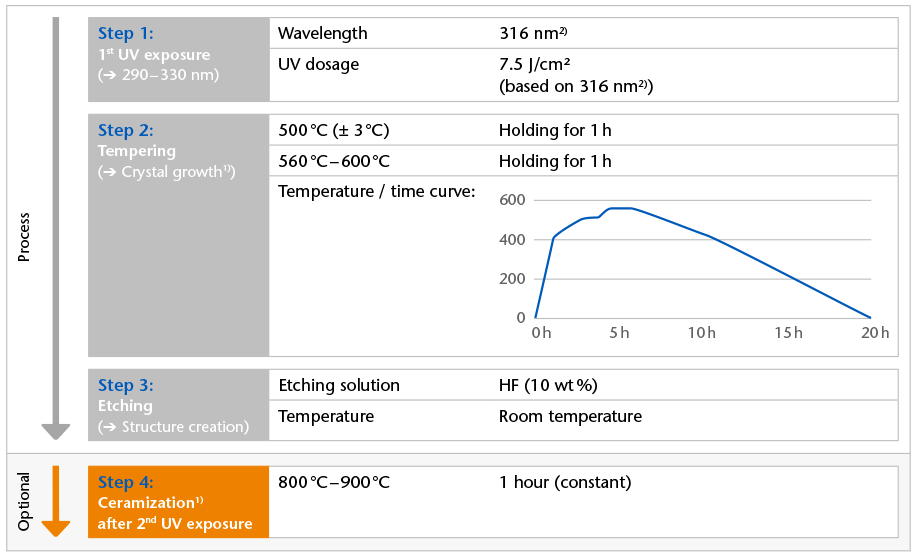

Standard photostructuring process

FOTURAN® II structuring consists of UV exposure, heat-treatment and etching - subsequent ceramization is optional

1) For 0.5 mm thick substrates – Parameter for other thicknesses may differ

2) Optimal theoretical exposure wavelength is 312 nm

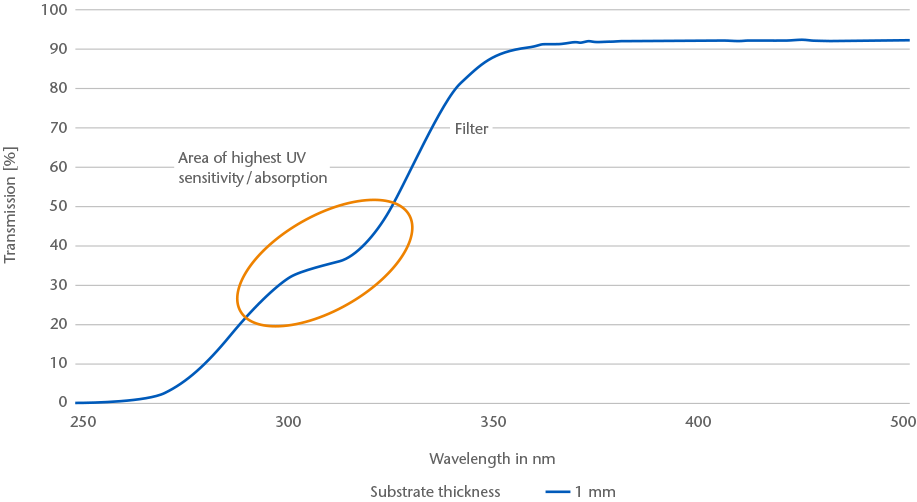

Transmission curve of unprocessed FOTURAN® II

The highest UV-sensitivity of raw FOTURAN® II is between 290 & 330 nm - Visible in the change of transmission slope