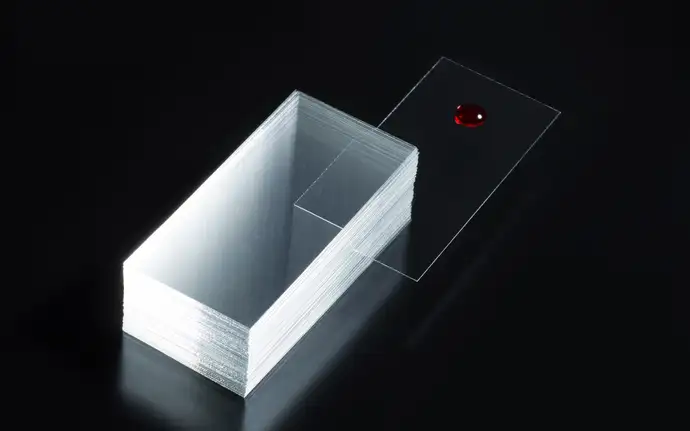

Glass for automated coverslipper

Automated coverslipper: a new era in microscopic analysis

The microscopy field is rapidly advancing, with the demands for precision and efficiency in sample analysis growing more acute. The integration of Artificial Intelligence (AI) in microscopy, particularly in enhancing image analysis and data interpretation, underscores a broader trend of digital innovation. This trend promises to significantly improve analysis accuracy and efficiency. Automated coverslipping, which has evolved considerably over the years, is central to meeting these changing requirements. It streamlines the traditionally time-consuming task of slide preparation, establishing itself as a standard in contemporary laboratories.

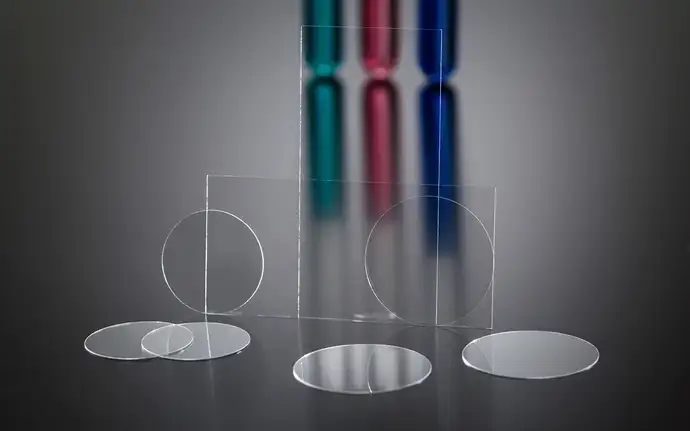

This progress is supported by the development of specialised borosilicate glass, whose properties seem to be tailored for automated coverslippers. Known for its clarity, durability, and chemical resistance, this glass is pivotal in producing high-quality, dependable slides. The compatibility of this glass with automated coverslipping equipment, alongside its unique features like uniform thickness and no image noise, is critical. As automated processes gain ubiquity, selecting the appropriate cover glass becomes a strategic decision that significantly impacts the quality of microscopic examinations.

Automated coverslipping, in concert with other laboratory automation technologies, has revolutionized specimen processing. The ongoing innovations in glass technology ensure that laboratories are well-equipped to face both current and future challenges in scientific analysis.

Enhancing laboratory efficiency and accuracy with automated coverslipping

Accelerating slide preparation

Uniform quality, every time

Protecting precious samples

Future-ready laboratories

The critical role of material selection in automated coverslippers: the case for glass

In the pursuit of excellence in microscopy, the choice of material for coverslips emerges as a pivotal factor, especially within the context of automated coverslipping technologies. While borosilicate glass is known for its superior properties, not all borosilicate glass is created equal. High-quality borosilicate glass, like that produced by SCHOTT, offers a suite of benefits tailored to enhance the precision, efficiency, and reliability of microscopic analyses.

Key benefits of D 263® M cover glass for automated coverslipping

D 263® M borosilicate glass, engineered by SCHOTT, meets the sophisticated demands of modern automated coverslipping systems, delivering unparalleled benefits that significantly enhance both efficiency and quality of microscopic analysis.

Non-sticky layer for stable separation and precision

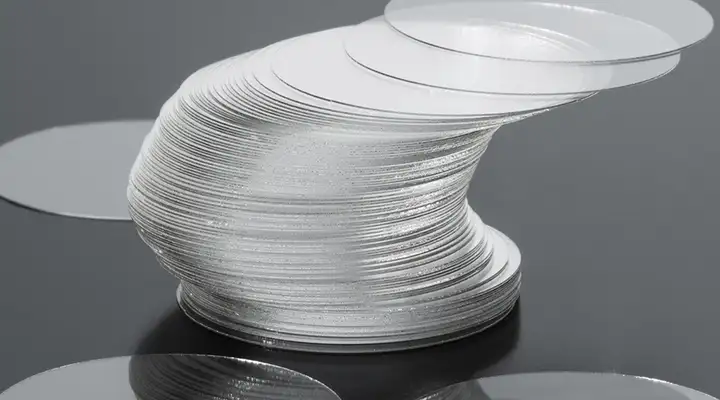

The separately applied non-sticky coating ensures effortless and resistance-free movement of the D 263® M, enabling a stable and smooth process. This feature enables fast and precise separation of the stacks without leaving residues or compromising the integrity of the samples. The ease of separation increases the efficiency of laboratory operations and improves the accuracy of results.

Enhanced processing stability with exceptional flatness

The high flatness of D 263® M reduces gaps when coverslips are stacked, ensuring smooth, consistent operations. This characteristic allows for uniformly stacked glass packages in cassettes or coverslip magazines, critical in high-throughput settings.

Superior bending strength for reduced breakage

With its edge finishing and homogeneous glass composition, D 263® M offers exceptional bending strength, which minimizes breakages during handling. This results in fewer interruptions for cleaning and enhances safety and consistency in automated coverslipping.

Enhanced durability with superior scratch resistance

Exhibiting a Knoop hardness of HK 0.1/20 470 and a Vickers hardness of HV 0.2/25 510, the hard surface of D 263® M allows for additional and extended handling without damage. This protects against scratches and surface defects, maintaining the quality of microscope slides.

Longevity and reliability with outstanding aging resistance

Rated at the highest hydrolytic stability HGB 1, D 263® M effectively resists corrosion due to water, humidity, and moisture over extended periods. This ensures reliable results and preserves sample integrity even after years of storage.

Exceptional durability for haze-free imaging

D 263® M has a high crystalline structure and exceptional durability, ensuring haze-free images. The high clarity of the image data enables accurate and reliable results without any background noise.

Improved imaging with low autofluorescence

The low autofluorescence of D 263® M, critical for applications such as fluorescence microscopy, ensures high image quality by eliminating background noise. This feature enables more precise diagnostic outcomes and supports additional lab-on-chip applications.

Consistent quality and compliance with ISO 8255-1

D 263® M strictly adheres to ISO 8255-1 standards, ensuring consistent thickness with precise tolerances up to ± 0,005 mm, and a uniform refractive index of 1.5255 ± 0.0015, which measures the glass's ability to bend light. Additionally, it has an Abbe value of 55, indicating low dispersion of light, critical for reducing optical distortions and enhancing image clarity in high-resolution microscopy applications. This compliance guarantees that every piece of glass meets rigorous industry standards, providing reliability in every application.

Optimized for AI-driven systems

In the context of AI-driven analysis, the quality of raw data is of paramount importance. The highly crystalline material D 263® M prevents interference and background noise, thereby providing AI systems with unadulterated raw data for precise analysis. This enables well-founded decisions to be made, which in turn leads to greater efficiency and precision in work processes.

FAQs

Borosilicate glass is preferred due to its superior optical clarity, chemical resistance, quality and reliability of microscopic analyses.

The high optical quality of borosilicate glass, characterized by minimal autofluorescence and consistent thickness, significantly enhances AI algorithms' ability to analyse slides accurately. This results in more reliable data interpretation, especially in complex imaging techniques where precision is crucial.

ISO 8255-1 compliance ensures that the cover glass meets global standards for dimensions, quality, and performance in microscopy. SCHOTT D 263® M is currently the only known material on the market to fulfil this cover glass standard, providing an additional layer of assurance in its suitability for automated workflows in high-precision microscopic analysis.

Yes, features like high homogeneity and strong transmittance across the UV to NIR spectrum make borosilicate glass particularly suited for fluorescence and super-resolution microscopy. These properties ensure clear and accurate imaging by reducing optical distortions and improving light transmission, critical for detailed specimen examination.

The available thickness range of borosilicate glass, from 0.1 to 0.21 mm, allows laboratories to select the optimal thickness for their specific analytical needs, enhancing slide preparation and imaging quality across a variety of microscopy techniques. For super-resolution microscopy, where even minute variations in thickness can affect imaging quality, SCHOTT has developed the D 263® M 1.5 H cover glass. This specialized glass features a reduced thickness tolerance of ± 0.005 mm, significantly improving resolution by ensuring uniformity across slides.

Borosilicate glass's chemical composition provides exceptional resistance to thermal shock, chemicals, and physical abrasion. This resilience makes it an ideal choice for use in high-throughput, automated coverslipping environments where reliability and durability are paramount.

The refractive index of borosilicate glass, such as SCHOTT D 263® M, is finely tuned for microscopy, ensuring minimal optical distortion and maximum light transmission. This precise refractive index supports accurate imaging and detailed analyses, crucial for applications requiring high-resolution, such as super-resolution microscopy and immunofluorescence studies. The accuracy and reliability it provides make borosilicate glass the ideal material for producing high-quality coverslips that meet the demanding standards of modern automated microscopy.

Stickiness between coverslips or between coverslips and equipment can significantly hinder the efficiency of automated coverslipping processes, leading to jams and potential damage to specimens. Borosilicate glass, known for its smooth, non-adhesive surface properties, mitigates this risk. The fire-polished surface of SCHOTT cover glass minimizes friction and prevents sticking, ensuring a seamless flow through automated systems. This feature enhances operational reliability and maintains the integrity of microscopic slides during high-throughput processing.

Marc Schneider

Head of Product Group Special Applications