Glass for Restoration

Produced by the historically accurate Fourcault method, SCHOTT glass for restoration are perfectly suited to buildings from the 18th, 19th and early 20th century, as well as the classical modern period. With ETA approval and a series of processing options, they have all the qualities needed for modern glazing.

Highly adaptable glass for authentic historical projects

Dimensions

GOETHEGLAS

| Dimensions GOETHEGLAS | |

|---|---|

| Max. dimensions* | 2,700 x 1,500 mm |

| Standard thickness* | 4.5 mm |

| Light transmission rate: | > 90% |

* Other dimensions and thicknesses available upon request

RESTOVER®

| Dimensions RESTOVER® | |

|---|---|

| RESTOVER® Light | |

| Max. dimensions | 2,700 x 1,500 mm |

| Standard thickness | 2.75 mm, 4.0 mm |

| Light transmission rate | > 90% |

| RESTOVER® | |

| Max. dimensions | 2,700 x 1,500 mm |

| Standard thickness | 2.0 mm, 2.75 mm, 4.0 mm |

| Light transmission rate | > 90% |

| RESTOVER® plus | |

| Max. dimensions | 2,100 x 1,500 mm |

| Standard thickness | 2.95 mm |

| Light transmission rate | > 90% |

TIKANA®

| Dimensions TIKANA® | |

|---|---|

| Standard dimensions* | 2,700 x 1,500 mm |

| Standard thickness* | 4.0 mm, 6.0 mm |

| Max. dimension in 6 mm thickness |

2,700 x 1,500 mm |

| Light transmission rate | > 90% |

* Other dimensions and thicknesses available upon request

ETA

Glass produced by SCHOTT’s special Fourcault drawn-glass process isn’t covered by the usual glass standards. Therefore, products using this process are also not subject to automatic regulation. ETA (European Technical Assessment) now confirms that SCHOTT Fourcault glass meets the requirements of the standards EN 12150-2, EN 14179-2, EN 14449 and EN 1279-5.

ETA represents an independent, Europe-wide valid certificate of performance for SCHOTT Fourcault glass as both a base glass and a processed product (toughened safety glass, laminated safety glass, laminated glass and insulating glass units). Extensive material testing at an accredited testing institute confirm the certified product properties.

ETA or abZ?

As part of European harmonization, the customary abZ (Germany’s national technical approval) is used only nationally when no European harmonized specifications are available. The ETA (European Technical Assessment) replaces the abZ for member states of the European Union.

The point of contact for both certifications is the Deutsches Institut für Bautechnik (DIBt – German Institute for Construction Technology).

Customer benefits

Customers can be assured that SCHOTT Fourcault glass can be processed into standard construction products, such as toughened safety glass, laminated safety glass, laminated glass and insulating glass units, in accordance with standards and can be designated as such.

That means no more time-consuming documentation and approval procedures, and processing options can be clearly communicated to customers using familiar terminology.

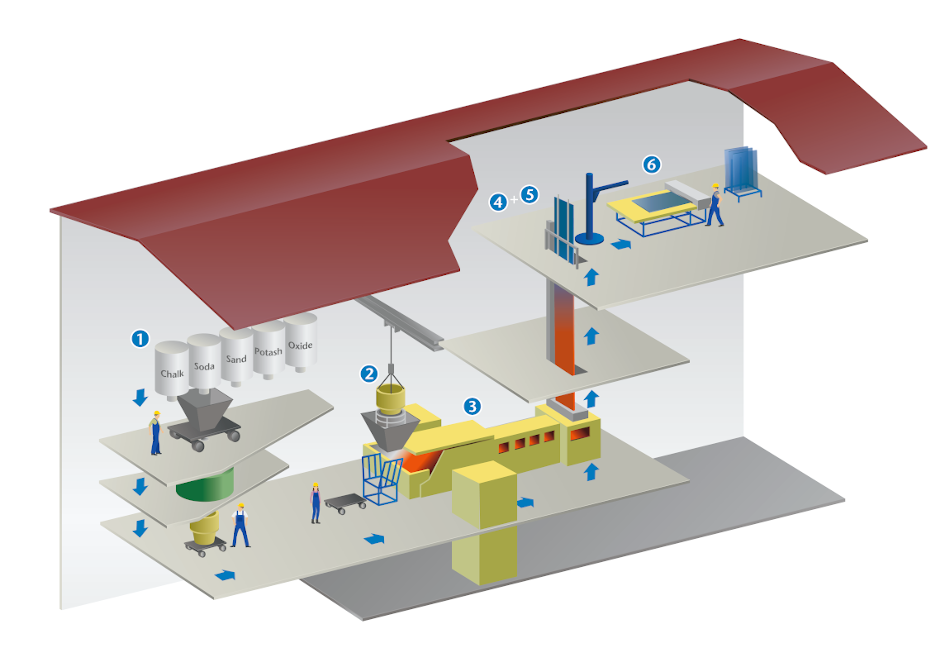

Production Process

SCHOTT glass for restoration are produced by the Fourcault process. In this process, molten glass is drawn through a Fourcault nozzle that produces the distinctive appearance of machine-drawn glass, with a certain thickness tolerance and wavy surface.

The Fourcault process involves six different stages:

- Preparation of batch

- Fill in of batch

- Glass melting

- Up-draw process

- Cooling down

- Edge cutting

FAQs

General Introduction

1. What is glass for restoration and how do it compares to normal window glass?

SCHOTT glass for restoration are specifically designed to offer accurate glazing solutions for historical buildings according to their date of origin. They offer the typical surface characteristics of different historical eras that can be integrated into the modern day requirements for insulated and laminated safety glasses.

Compared to normal window glass, SCHOTT glass for restoration offers state of the art technology in a historically correct design.

2. What colour are SCHOTT Restoration Glasses?

SCHOTT glass for restoration variants are colourless and particularly low in iron oxide. They are therefore highly pure and do not have the "green tint" typically found in conventional float glass. SCHOTT glass for restoration has a high transmission of visible light making it ideal for glazing buildings where naturally bright internal conditions are important.

3. What are the differences between the different SCHOTT restoration glass variants?

SCHOTT glass for restoration has the typical tensile strength of the manufacturing process. In addition, they are - depending on the product - more or less distorted.

- RESTOVER® light: slightly uneven surface

- RESTOVER®: irregular surface, wavy and expressive

- RESTOVER® plus: strongly structured surface with distinct waviness

- GOETHEGLAS: full of character and irregular

- TIKANA®: slight tearing stripes

SCHOTT recommends a sample of at least 500 mm x 500 mm sample glass for the correct glass selection. Please evaluate the optics in the reflection (external view) and in the transmission (internal view).

4. How is SCHOTT glass for restoration manufactured?

SCHOTT glass for restoration is manufactured using the traditional Fourcault process. The glass is drawn vertically upwards from the liquid melt through a nozzle via a drawing shaft. At the end of the drawing shaft, the glass is cut to sheet size.

Certain variations in surface structures are also possible and permissible within a product/plate.

5. What does tensile strength mean?

By vertically pulling the glass mass through the nozzle, the glass becomes distorted in parallel to the direction of drawing. When viewing through the glass, this distortion is more noticeable if the glass is installed vertically as opposed to horizontally. Sampling is also recommended here.

6. Does SCHOTT glass for restoration has bubbles, knots, stones or similar?

Such glass characteristics are possible due to the melting conditions and are permissible within certain specifications. However, they do not protrude from the glass surface.

7. What are the maximum dimensions?

SCHOTT glass for restoration can be manufactured up to a length of 2,900mm and is therefore suitable for many buildings from the gothic revival period, Victorian era, Edwardian era righ through to art deco and postmodern architecture.

Processing

1. What must be considered when cutting the glasses?

Machine-drawn glass has a higher residual cooling stress and greater distortion than float glass due to the manufacturing process. The cutting must therefore be carried out with an expansion cut and under consideration of certain cutting wheel angles and cutting pressures.

2. Is thermal tempering possible?

SCHOTT glass for restoration can be thermally tempered. Our application technology department will be happy to assist you with detailed questions. Click here to open our contact form.

3. Is it possible to produce laminated glass?

Processing to laminated glass using conventional PVB films is possible. A thicker film is required to compensate for thickness variations. If a counter pane of float glass is used, the optical impression of the glass for restoration diminishes when viewed through. We recommend sampling. If special UV or IR filter films are used for lamination, SCHOTT glass for restoration is ideal for glazing museums or sacral buildings with increased lighting requirements in connection with monument protection. Soundproofing foils contribute to the reduction of noise pollution in buildings.

4. Can glass for restoration be used for insulating glass?

Insulating glass can be produced using glass for restoration. As a rule, the outer pane of the insulating glass is designed as a glass for restoration, the inner pane is made of white glass or float glass, if necessary with a thermal insulation coating. Selected glass for restoration can also be provided with direct sun protection layers to improve thermal insulation in summer. If 4 mm wide spacers are used in insulating glass, insulating glass with a total thickness of approx. 10 mm can be built.

5. Are there specifications and structural approvals for SCHOTT glass for restoration?

The physical, chemical and technical properties of all SCHOTT glass for restoration variants are described in the specifications. In addition, all SCHOTT glass for restoration variants have the European Technical Approval ETA-12/0159 of the German Institute for Construction Technology, i.e. depending on the thickness of the glass, it can be easily processed into standard construction products such as ESG, laminated safety glass and insulating glass and placed on the market without bureaucracy.