Technical Details of NEXTREMA®

Common properties for all six NEXTREMA® variants

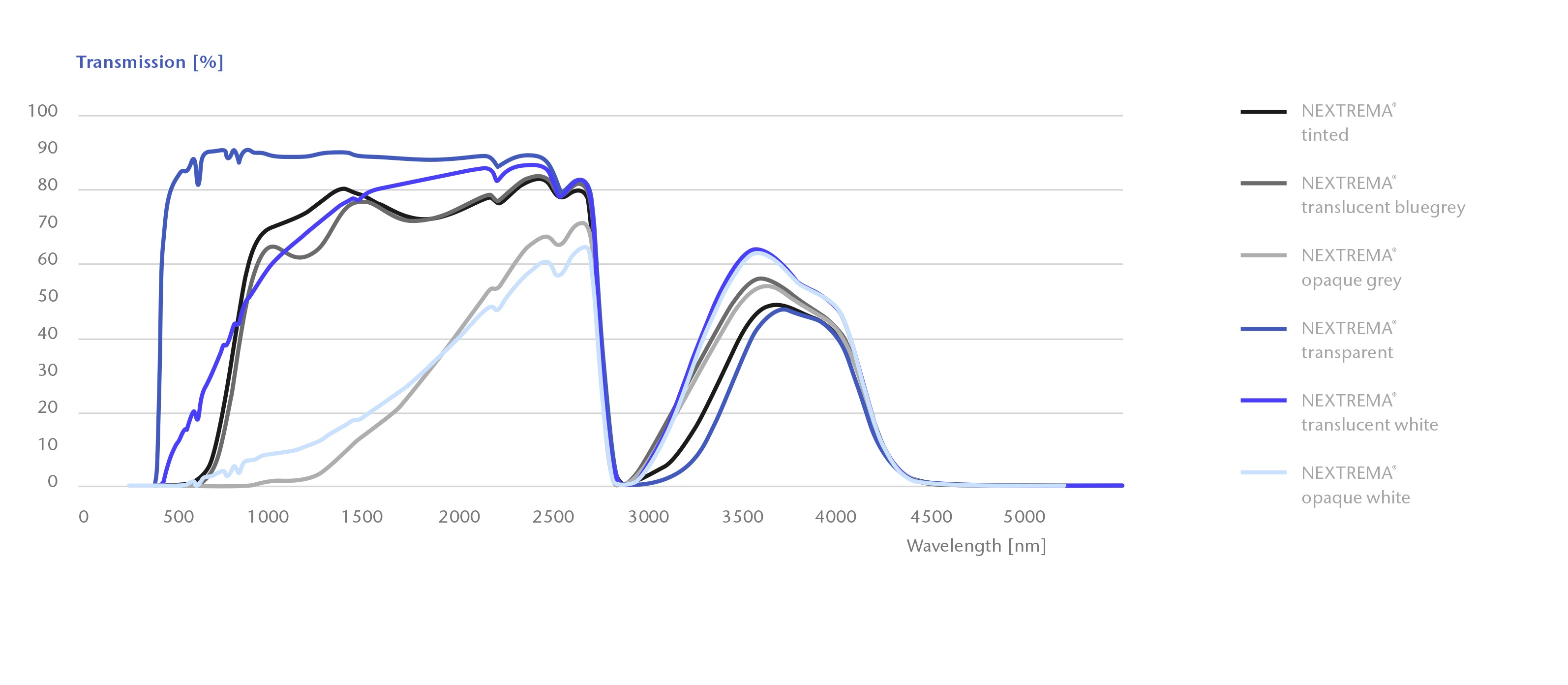

SCHOTT NEXTREMA® optical properties

NEXTREMA® offers six transmission profiles in the visible and infrared range depending on material type and material thickness. For engineers and designers, that means NEXTREMA® is the material of choice when it comes to light transmission and infrared radiation, for example in radiant heaters. The six different NEXTREMA® variants offer a transmission portfolio dependant on your needs, making this a reliable material partner for industry and home.

| Key properties | Benefits | tinted (712-3) |

translucent bluegrey (712-6) |

opaque grey (712-8) |

transparent (724-3) |

translucent white (724-5) |

opaque white (724-8) |

|---|---|---|---|---|---|---|---|

| 6 transmission profiles in visible range (400 - 800 nm) | 6 design options | black | blue | grey | transparent | white | white |

| Glare reduction | yes | yes | yes | yes | yes | ||

| Light diffusion | yes | yes | |||||

| Light blocking | yes | yes | |||||

| 6 transmission profilesin infrared range (800 - 4500 nm) | Efficient IR heater cover | yes | yes | yes | yes | ||

| Selective IR transmission | yes | yes | |||||

| Compatible with different IR heaters | yes | yes | yes | yes | yes | yes |

Transmission

Transmission values are measured for a polished sample of a specific thickness.

This graph is based on data from individual measurements. Deviations may result from the manufacturing process. Typical transmission graph of different ceramization states with sample thickness of approximately 4 mm (0.157 in).

SCHOTT NEXTREMA® mechanical properties

NEXTREMA® boasts a very high degree of mechanical strength for a ceramic material and doesn’t require any additional toughening processes. The glass-ceramic also exhibits extraordinary mechanical stability, even at high temperatures. The NEXTREMA® variant with the highest bending strength is tinted (712-3), which can withstand a force of up to 165 megapascals.

| Key properties | Benefits | tinted (712-3) |

translucent bluegrey (712-6) |

opaque grey (712-8) |

transparent (724-3) |

translucent white (724-5) |

opaque white (724-8) |

|---|---|---|---|---|---|---|---|

| Bending strenght of up to 165 MPa (thickness 4mm/0.157 in) | High material streght without tempering | yes | yes | yes | yes | yes | yes |

| Reliable material strenght under high temperatures | yes | yes | yes | yes | yes | yes | |

| Surface/ Knoop harness of up to 620 | Good abrasion resistance | yes | yes | yes | yes | yes | yes |

| Density of ~2,5 g/cm3 | Lightweight compared to technical ceramics | yes | yes | yes | yes | yes | yes |

- Density: ρ approx. 2.5 – 2.6 g/cm3

- Modulus of elasticity (ASTM C-1259): E approx. 84 – 95 x 10³ MPa

- Poisson‘s ratio (ASTM C-1259): μ approx. 0.25 – 0.26

- Knoop hardness (ISO 9385): HK0.1 / 20approx. 570 – 600

- Bending strength (DIN EN 1288, Part 5, R45): σbBapprox. 100 – 165 MPa

- Porosity (ISO 9385): 0 %

- Roughness: Material 724-3 (t = 4 mm/0.157 in) Ra≤ 0.20 μm Rms ≤ 0.25 μ

Impact resistance

The impact resistance of NEXTREMA® depends on the size, thickness and geometry of the panel, kind of installation and type of impact, especially on drilled holes and their position in the material. Therefore, information regarding impact resistance can only be given with knowledge of the respective and defined application, especially in combination with the technical standards regarding impact resistance that have to be met for some applications. The quality of the grinding profile also has an important influence on impact resistance.

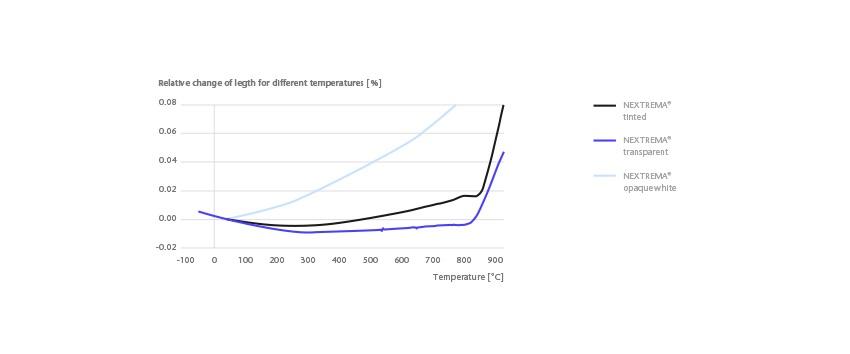

SCHOTT NEXTREMA® thermal properties

NEXTREMA® exceeds all expectations when it comes to temperature resistance. The material can withstand both extremely high and low temperatures, offering outstanding resistance up to 950 °C (1,742°F)1 (depending on the material type). From white hot to ice cold and back again, quick changes in temperature will have little impact on this heat resistant glass-ceramic, minimizing thermal stress fractures. Thanks to its near-zero thermal expansion, NEXTREMA® can also cope with temperature shocks of up to 820 °C (1,508°F)2 (depending on the material type), making it ideal for high-temperature applications.

1 Applies to NEXTREMA® opaque white for 1 hour at 950°C (1,742°F) homogenous heating. For inhomogeneous heating and other NEXTREMA® variants, the operating temperature may vary.

2 Applies to NEXTREMA® transparent. Tested by quenching a homogeneously heated NEXTREMA® transparent panel (820°C /1,508°F) with room temperature water (20°C /68°F). Values may differ for other NEXTREMA® variants.

|

Benefits |

tinted |

translucent bluegrey |

opaque grey |

transparent |

translucent white |

opaque white |

|---|---|---|---|---|---|---|

|

Reliable performance when exposed to thermal shocks |

yes |

yes |

yes |

yes |

yes |

yes |

|

Resistance to Temperature Differences (RTD) |

Tupper max1 ≤ 700°C (1,292°F) |

On demand |

On demand |

Tupper max1 ≤ 700°C (1,292°F) |

Tupper max1 ≤ 560°C (1,040°F) |

Tupper max1 ≤ 580°C (1,076°F) |

|

Rapid cooling down from extreme temperatures without cracking |

yes |

yes |

yes |

yes |

yes |

yes |

|

Dimensional accuracy under fluctuating temperature conditions |

yes |

yes |

yes |

yes |

yes |

yes |

|

Coefficient of Mean Linear Expansion α(20; 700°C) (DIN ISO 51045-1, DIN ISO 7991) |

0 ± 0.2 x 10-6 K-1 |

On demand |

On demand |

0 ± 0.5 x 10-6 K-1 |

1.0 x 10-6 K-1 |

1.0 x 10-6 K-1 |

1 Tupper max : Maximum temperature on the upper side at the hottest point

2 Tes, max : Maximum temperature on the exterior side of the panel, that means the reverse side of the heat source, at the hottest point

Thermal expansion depending on the temperature

Resistance to Temperature Differences (RTD)

-

Resistance of the NEXTREMA® material to temperature differences which are measured at a distance of 25 mm between hot and cold zone (room temperature).

-

Translucent white: No cracking due to thermal stress at Tupper max1 ≤ 560°C (1,040°F)

-

Opaque white: No cracking due to thermal stress at Tupper max1 ≤ 580°C (1,076°F)

-

Tinted & Transparent: No cracking due to thermal stress at Tupper max1 ≤ 700°C (1,292°F)

-

Translucent bluegrey & Opaque grey: on demand

1 Tupper max : Maximum temperature on the upper side at the hottest point

Thermal schock resistance (TSR) up to 820°C (1,508°F)

Resistance of the material to thermal shock when the hot material is splashed with cold water at room temperature, without cracking due to thermal stress. NEXTREMA® transparent is the glass-ceramic with the highest resistance to temperature shocks out of all six NEXTREMA® variants. NEXTREMA® transparent panels resist to thermal shock when homogeneously heated up to 820°C (1,508°F) and quenched with 20°C (68°F) room temperature water.

That means no cracking due to thermal stress. Values differ for other NEXTREMA® variants.

Temperature/time load capacity (TTLC)

The TTLC specifies the maximum permissible temperatures for load times of the material, below which no cracking should occur due to thermal stress. The Temperature/Time Load data for uneven and even temperature distributions (e.g. homogeneous heating conditions) within the material are different.

|

Load time |

tinted |

Translucent bluegrey |

Opaque grey |

transparent |

Translucent white |

Opaque white |

|---|---|---|---|---|---|---|

|

TTLC/ 10h |

≤ 700°C (1,292°F) |

On demand |

On demand |

≤ 700°C (1,292°F) |

≤ 580°C (1,076°F) |

≤ 600°C (1,112°F) |

Temperature/time load capacity for nonuniformly heated glass-ceramic panel. Temperature/time load capacity is higher for homogenous heating. Operating temperature for NEXTREMA® opaque white for 1 hour homogenous heating is up to 950°C (1,742°F). For other NEXTREMA® variants, the operating temperature may vary.

SCHOTT NEXTREMA® chemical properties

NEXTREMA® is chemically resistant and remains stable in aggressive environments. It meets all subsequent ISO and DIN standards in its chemical resistance to acids, bases and hydrolytic influences. With the elimination of degradation enabling reliable material behavior, as well as stable process environments under typical corrosive conditions. This chemical- and base-resistant glass-ceramic is used in all fields of industrial and product design.

| Key properties | Benefits | tinted (712-3) |

translucent bluegrey (712-6) |

opaque grey (712-8) |

transparent (724-3) |

translucent white (724-5) |

opaque white (724-8) |

|---|---|---|---|---|---|---|---|

| High chemical resistance comparable to laboratory glassware | Comparable resistance to laboratory glassware | yes | yes | yes | yes | ||

| Reliable protection against corrosive environments | yes | yes | yes | yes | |||

| Non-porous, smooth surface | No outgassing in vacuum environments | yes | yes | yes | yes | yes | yes |

| No generation of particles without external influence | yes | yes | yes | yes | yes | yes |

Principal constituents (DIN EN 1748-2-1)

| Component | Symbol | Percentage per mass |

|---|---|---|

| Silicon dioxide |

SiO2 |

50 % – 80 % |

| Aluminium oxide | Al2O3 |

15 % – 27 % |

| Lithium oxide |

Li2O |

0 % – 5 % |

| Zinc oxide |

ZnO |

0 % – 5 % |

| Titanium oxide |

TiO2 |

0 % – 5 % |

| Zirconium oxide |

ZrO2 |

0 % – 5 % |

| Magnesium oxide |

MgO |

0 % – 8 % |

| Calcium oxide |

CaO |

0 % – 8 % |

| Barium oxide |

BaO |

0 % – 8 % |

| Sodium oxide |

Na2O |

0 % – 2 % |

| Potassium oxide |

K2O |

0 % – 2 % |

| Other (trace content on request) | 0 % – 5 % |

The materials do not contain any harmful substances according to the European directive 2011/65/EU “Hazardous Substances in electrical and electronically Equipment” and fulfil the terms of RoHS(II) without any concerns. NEXTREMA® glass-ceramics consist of 100% UVCB substance glass. According to REACH, this kind of glass is not classified as a hazardous substance. When used within the limitation of the according material specification, NEXTREMA® glass-ceramics do not release any hazardous substances throughout the entire life cycle (including the disposal), that would violate existing legal limits.

End of life usage

Federal Republic of Germany waste disposal regulations differentiate five classes of waste: Z0 (non-restricted disposal), Z3 (household waste), and up to Z5 (highly toxic waste). All NEXTREMA® materials are classified as non-restricted disposal. Local government regulations may differ. Please contact the local authority if needed. NEXTREMA® must not be disposed of in recycling boxes for standard glass (e g. glass bottles).

Chemical resistance

The chemical resistance of NEXTREMA® is more extensive than that of most other comparable materials.

| Tinted (712-3) | Translucent bluegrey (712-6) | Opaque grey (712-8) | Transparent (724-3) | Translucent white (724-5) | Opaque white (724-8) | |

|---|---|---|---|---|---|---|

| Hydrolytic Resistance HGB (ISO 719) | 1 | 1 | 1 | 1 | 1 | 1 |

| Acid Resistance S (DIN 12116) |

2 | 2 | 2 | 2 | 1 | 1 |

| Alkali Resistance A (ISO 695) |

1 | 2 | 2 | 1 | 1 | 1 |

1 = high resistance / low solubility

2 = medium resistance / medium solubility

3 = low resistance / high solubility