Mirror substrates for satellites

Understanding the challenges in satellite design

Where precision matters most: Satellite applications

Earth observation and meteorology

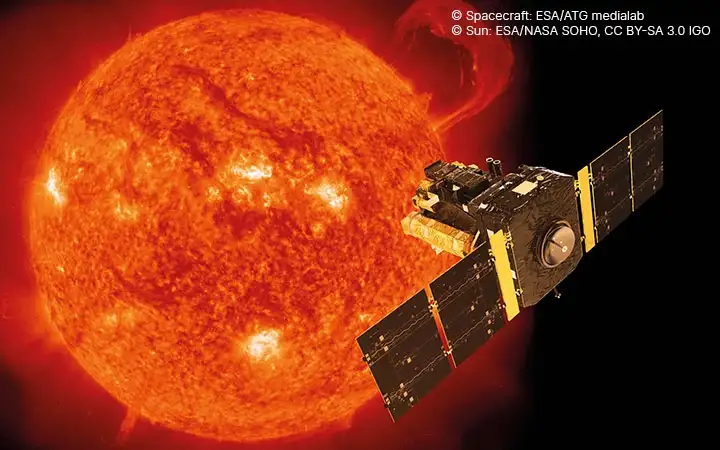

Astronomy and space science

Laser communications and technology demonstrators

Solar and planetary science

Partnering with satellite designers

At SCHOTT, we don’t just deliver materials — we collaborate with engineers to design optical and structural components that meet the most demanding specifications. Our support spans from material selection and machining to lightweighting, high precision grinding, and metrology.

We’ve partnered with leading agencies and system integrators — including ESA, NASA, CNES, ISRO, and JAXA — to build flight-proven solutions across decades of missions.

Our mission: To help yours succeed — with materials that ensure precision, reliability, and stability in orbit.

ZERODUR®: Enabling stable optics in space

Mean coefficient of linear thermal expansion

ZERODUR® glass-ceramic is supplied with a mean coefficient of linear thermal expansion (CTE) in the temperature range 0°C to 50°C in six expansion classes as follows:

| CTE (0°C; 50°C) specification tolerances | |

|---|---|

| Expansion Class 2 | 0 ± 0.100 ppm/K |

| Expansion Class 1 | 0 ± 0.050 ppm/K |

| Expansion Class 0 | 0 ± 0.020 ppm/K |

| Expansion Class 0 Special | 0 ± 0.010 ppm/K |

| Expansion Class 0 Extreme | 0 ± 0.007 ppm/K |

| CTE optimized for application temperature profiles | |

| ZERODUR® TAILORED | 0 ± 0.020 ppm/K (± 0.010 ppm/K upon request) |

When thermal expansion is not an option, ZERODUR® delivers. With an near-zero coefficient of thermal expansion (CTE), exceptional homogeneity, and radiation resistance, it’s the reference material for space optics.

| Design challenge | ZERODUR® solution |

|---|---|

| Thermal distortion | Near-zero CTE maintains shape under temperature swings |

| Alignment drift | Dimensional stability ensures long-term optical precision |

| Surface quality | Excellent polishability for nanometer-level surfaces |

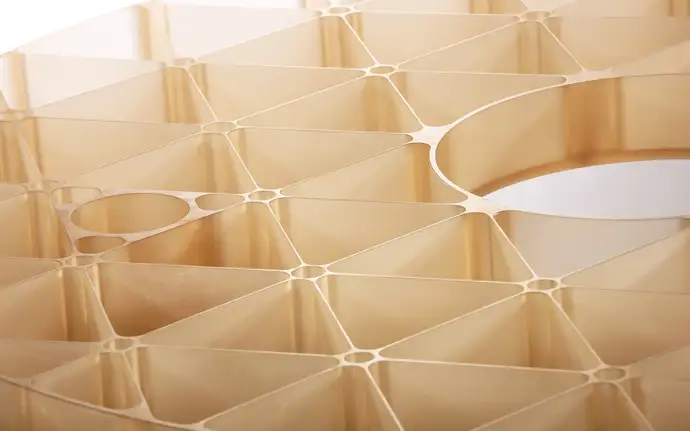

| Weight constraints | Available in customized lightweighted configurations |

| Harsh environment | Proven radiation and vacuum stability |

Learn more about the material properties on the ZERODUR® product page →

Space-proven heritage

For over 40 years, ZERODUR® has been part of flagship satellite missions across multiple disciplines:

FAQs

What materials are used for satellite mirrors?

Satellite mirrors often use glass-ceramics like ZERODUR® for their near-zero thermal expansion and high optical quality.

Why is thermal stability important in space?

In orbit, temperature swings can cause ordinary materials to expand or contract, distorting optics and misaligning instruments. Thermally stable materials prevent this.

What makes ZERODUR® suitable for satellites?

Its near-zero CTE, radiation resistance, and long flight heritage make it ideal for high-precision optical systems in space