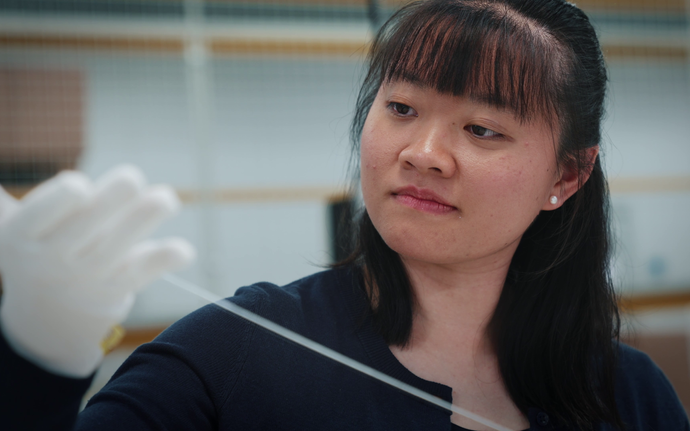

PURAVIS®

Extraordinary properties for precise performance

Available in a range of diameters, SCHOTT PURAVIS® glass optical fibers feature a range of unique technical benefits, including exceptional transmission of white light and large acceptance angles. Taken with low color shift and low attenuation in the visible range, these remarkable fibers are able to handle extremely challenging conditions with high consistency and precision.