HEATAN®

Ready now for next-generation automotive sensors

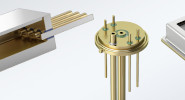

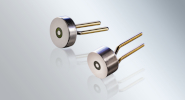

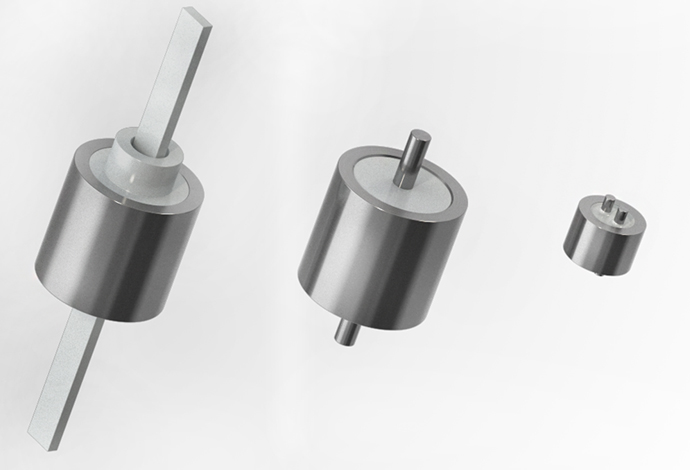

The exceptional heat and corrosion resistance of HEATAN® feedthroughs makes them ideally-suited for all heat-exposed automotive sensors. They can be fully custom-designed to specific requirements. Superior robustness makes HEATAN® the first choice in engine management systems, exhaust management technologies, temperature sensors, and pressure sensors.

Enabling simpler, more economical high-temperature sensors

HEATAN® sensor feedthroughs are single-component solutions that simplify the process of assembling sensor sealing systems for applications above 1000°C by using fewer components and a more cost-effective assembly. In contrast, conventional multi-component sensor sealing assemblies require several manufacturing steps to achieve the required high-temperature properties.

Product properties

HEATAN® feedthroughs utilize unique glass-ceramic technology and were developed based on decades of expertise as a leading supplier to the automotive and sensor industries. By integrating feedthroughs from SCHOTT into high-temperature sensor designs, customers benefit from excellent temperature and corrosion resistance.

Explore product properties in detailTo protect your privacy, external content will only be loaded with your consent. Refer to our Cookie Policy for detailed information.

-

How to design simpler high temperature sensors.

-

HEATAN® sensor feedthroughs can be custom-designed according to specific requirements.

-

The secret behind the superior high temperature robustness of HEATAN®.

We are certified

HEATAN® feedthroughs are produced in production facilities that are certified according to: IATF 16949 corresponding to QS 9000/VDA 6.1, ISO 9001 and ISO 14001.

Related products

Want to know more? Let’s talk

Whether you need more information, samples, a quote, or advice for a project, I would be delighted to talk to you.

Contact us