When is hermetic really hermetic?

“Hermetic” is a word that is commonly misused. While often used synonymously with wording such as “airtight,“ the official definition refers to a seal that is gas tight and will keep both moisture and harmful gases from penetrating into a sealed electronic package. It equally signifies that the package can keep gases, liquids, or other substances from escaping.

How does moisture affect electronics?

Even very small amounts of water vapor inside an electrical housing or system can compromise the performance and reliability of the encapsulated electrical or optical components e.g. semiconductor chips. This is why internal moisture levels must be kept low enough to even avoid condensation, as its consequences on sensitive electronics can be severe and cause component or complete system failure. The effects include

- Chemical corrosion, causing damage to the metal interconnects

- Electrical leakage across conductors / pins

- Electrical shorts due to dendritic growth of silver and gold

- Light scattering or wavelength drift in photonic components

Adequate hermetic packaging and sealing materials: glass, metal, ceramics

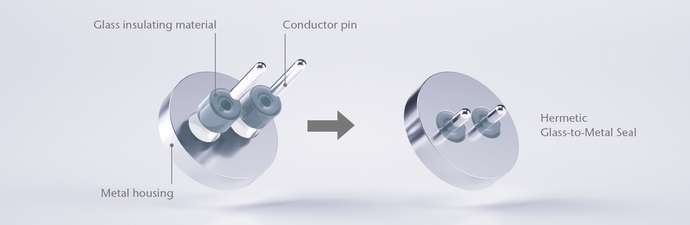

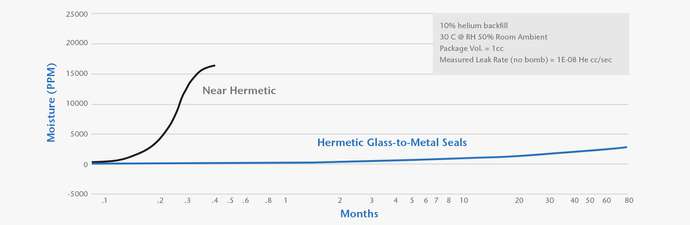

Only packages and seals made from glasses, metals, and ceramics are considered hermetic. These materials are all inorganic, virtually non-aging, and inherently have permeation levels close to zero. Depending on the design and application, a high-quality hermetic package using these materials can keep moisture levels inside a package below the required 5000 PPM (parts per million) threshold for many years or even decades (see fig. 1).

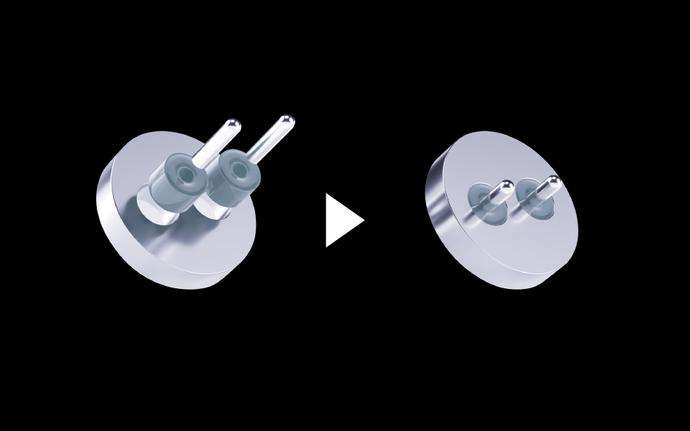

Hermetic sealing with glass provides reliable, non-permeable insulation of conductors while enabling electrical power or signal transmission.

Definition of “hermeticity”

The universally accepted test to determine hermeticity is “MIL-STD-883 Test Method 1014.” Historically developed to test safety-relevant microelectronic components in military, aerospace, and class III medical implants, this method is nowadays also widely used as a reliability measure in applications that include automotive airbags, industrial and energy, and even consumer electronics.

To be considered hermetic, the internal moisture content inside a cavity package must not exceed 5000 parts per million (PPM) over the lifetime of the device. At 5000 PPM, the dew point is far below the freezing point, rendering any residual moisture into ice crystals that would not cause corrosion. In comparison: even at relatively dry moisture levels – for example, 8000 parts per million – condensation will form inside the package at a temperature of around 5°C.

Fig 1: Hermetic glass-to-metal seals are designed to keep the moisture content below critical levels over the lifetime of a device.

How to test hermeticity

The most common method to test a sealed package or system for hermeticity is the “fine leak” test, which measures the rate at which the tracer gas helium escapes from a package. In this test, the package is exposed to high helium pressure, which – in case of any leaks – would lead to helium molecules penetrating into the enclosure. The package is subsequently exposed to pumping in a vacuum test chamber in which escaping helium can be detected. According to the measured helium leak rate, the standard leak rate (which would apply at “normal” operating conditions of 25°C and atmospheric pressure) needs to be calculated.

If the package is not exposed to helium pressure long enough, or if it is compromised to the point that helium immediately escapes, the fine leak detection test could lead to an incorrect conclusion that the component is gastight. This is why a “bubble” or “gross leak” test is required in addition, which detects any severe leaks.

Using the helium test method, even ultra-fine leaks can be detected. However, this is only possible under laboratory conditions and requires long pumping and measurement cycles. In addition, packages with small cavities / volumes require a higher specified gas-tightness, because they would otherwise reach the 5000 PPM threshold more quickly than those with a larger volume. That is why the specified hermeticity value is dependent on both the test conditions and the package design.

Near-hermetic, quasi-hermetic or non-hermetic

When the term “near hermetic,” “quasi-hermetic,” “almost-hermetic,” or “non-hermetic” packaging is used, it implies the package is made from polymeric materials or plastics (e.g. liquid crystal polymer, or LCP) as opposed to glasses, metals, and ceramics. No matter whether a package is referred to as near- or quasi-hermetic, it always has to be considered non-hermetic as per the above definition.

Polymers and epoxies: high permeation rates and natural aging

While many everyday applications use polymers, epoxies, or PEEK as sealing or packaging materials, they do not offer true hermeticity and must always be considered non-hermetic.

The core downside of these materials is that they are organic in nature, which means they have an inherently high permeation rate. They age naturally over time and will eventually allow moisture to penetrate into a sealed system. This aging process progresses even more quickly under environmental influences such as high temperature, pressure, or chemicals, which can lead to severe leakage issues caused by the sealing materials.

In addition, outgassing during the curing process or during operation can compromise the ambient environment, leading to critical rates of vapor pressure, moisture levels, and condensation.

In practice this means non-hermetic packages are typically used for applications with lower reliability and operational requirements. Hermetically sealed components, on the other hand, can fulfill enhanced needs for longevity, harsh environment reliability, as well as performance and efficiency increases.

Why helium leak testing is misleading in case of organic packages

Using the helium fine leak test method for packages made with polymers, PEEK, or plastics cannot provide reliable results for one major reason: it measures leakage, but not permeation and specifically does not account for the high permeation rate of organic materials over time that is several orders of magnitude higher than that of metals, glasses, and ceramics. This means an organic package may be sufficiently “helium-tight” at the time of testing simply because of exposure to only a very short test cycle. Since polymeric materials have an inherent diffusive and absorbent characteristic with a high permeation conductivity, non-hermetic packages can reach critical moisture levels after a period of just a few days to several weeks. This is caused by diffusion of water and other gases through the polymer structure.

Conclusion: decision for hermetics

The decision whether to go for truly hermetic or non-hermetic packaging usually depends on the sensitivity of the components to moisture and harmful gases, performance requirements, technical design specifications, and operating conditions. Oftentimes, hermeticity or a specific leakage rate may not be a fixed quality requirement, but the hermetic seal can be the enabler to fulfill other needs, such as resistance to extreme temperatures or pressure, superior longevity, increased demands regarding performance or efficiency, or all of them at the same time.

You might also like

Elisabeth Fey

Head of Strategic Marketing Electronic Packaging