Oil and gas equipment

Battling against the harshest conditions on earth

Oil and gas equipment must not only survive, but function flawlessly under extreme pressure, vibrations, and temperatures. Failure is not an option for electrical and optical components as equipment deep underground is inaccessible for easy repairs or replacement due to prohibitively high costs.

Pressure sensors in oil and gas subsea production must withstand extremely harsh HPHT (high temperature, high pressure) environments and require a very long design lifetime of more than 25 years. In contrast, sensors in oil & gas exploration applications (such as Wireline, MWD, and LWD) are typically exchanged after several years. However, the pressure requirements in these downhole drilling applications are some of the harshest on earth. A potential weak point of these systems is the robustness and longevity of the electrical connectors and hermetic packages that are needed to transmit valuable data and information provided by the sensors.

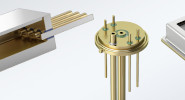

Components for extreme temperature and pressure found in oil & gas environments

Deep underground in oil & gas drilling areas, 35,000 PSI (2413 bar) pressure and temperatures in excess of 260 ºC (500 º F) represent typical conditions. Drills and measurement equipment must withstand these conditions as maintenance and replacement is nearly impossible, and downtime is costly in case of failures. These conditions were previously nearly impossible to reliably withstand using conventional thermoplastic connectors and components. Hermetic glass-to-metal sealing engineering, on the other hand, can reliably uphold mechanical stability in such extreme conditions.

In subsea oil & gas applications, glass-sealed electrical connectors from SCHOTT offer proven maintenance-free longevity even after many years of use that can prevent costly component replacements They are designed to withstand 20,000 PSI (1379 bar) pressure and temperature ranges from -170 º C to +450 º C (-274 º F to +842 º F).