Microarray solutions

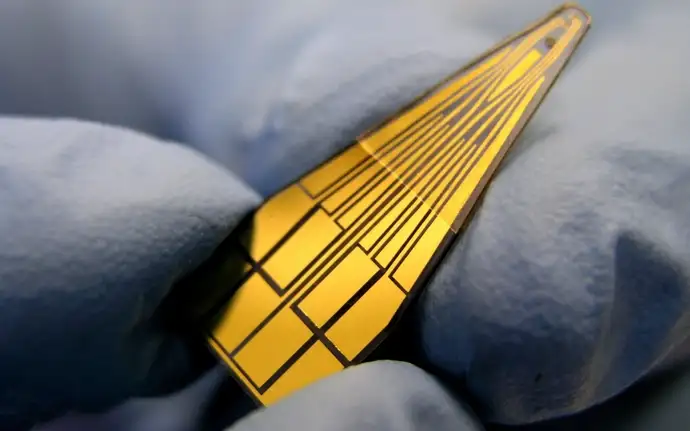

Our unique microarray printing technology

Over two decades ago, we pioneered the first generation microarray printer in response to the demands of the Human Genome Project, filling a crucial gap in available technology. Since then, we've relentlessly refined and expanded this platform, transforming it into a truly unparalleled solution.

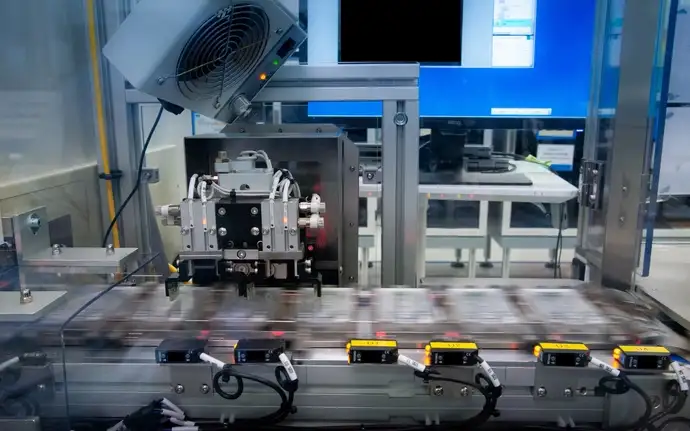

Today, our advanced microarray printing technology stands out for its ability to deliver precision, high throughput, and flexibility, setting a new standard in microarray printing.

Unmatched capacity and flexibility

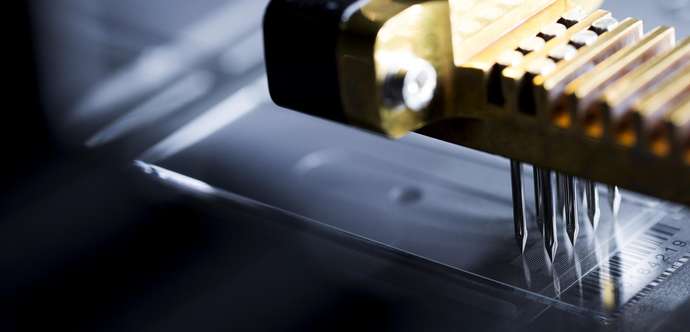

Our Proprietary Non-Contact Piezo Printing Technology

| Feature | Description |

|---|---|

| Drop Volume | 20pL – 300pL single drop volumes Higher dispense volumes with stop-and-drop firing mode |

| Spot Size Range | 25µm -300µm |

| Print Mode | On-the-fly or stop-and-drop with a single drop or stop-and-drop with multi-drop firing |

| Print Speed | Deposit of 32 unique biomaterial samples on every pass at a rate of 238 spots per second |

| Print Tips | Up to 32 tips possible |

| Print Type | Non-contact printing |

| Biomaterials | Dispensing a broad range of biomaterials (nucleic acids, proteins, complex antigens, peptides, etc.) in spotting buffers of varying composition and density |

| Substrates | Production of arrays on a wide range of substrate materials, including glass, plastic, or silicon, in standard or custom shapes and sizes |

| Batch Sizes | Standard batch sizes are up to 136 standard microscope slides or 32 microtiter plate-sized glass |

Our advantages

We sell microarrays, not printers

Repeatable manufacture of high-quality microarrays is about much more than just the printing technology. It requires control of the environment, precise preparation of reagents and substrate surfaces, optimization of printing parameters, thorough post-processing and stringent quality control. With our exclusive dispensing technology and expertise, we offer a unique proposition: entrust us with your microarray manufacturing needs. As pioneers in the field, we exclusively offer contract development and manufacturing services, underscoring our commitment to not merely providing the right tool for the job, but to finish the job for you.

Applications

No matter your microarray application, we've likely encountered something similar and can assist you on your journey. With our experience and expertise, we will help guide you to success.

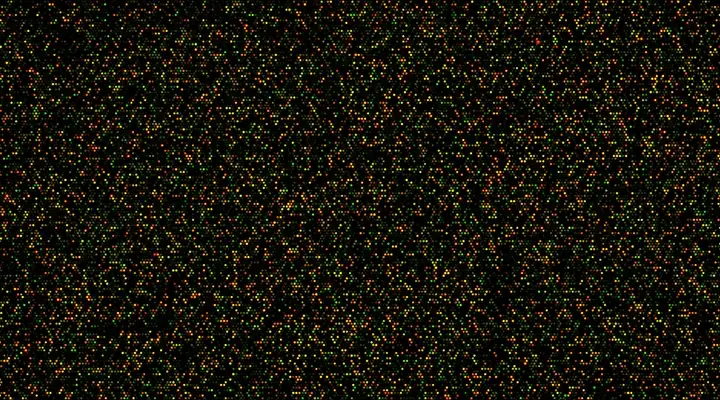

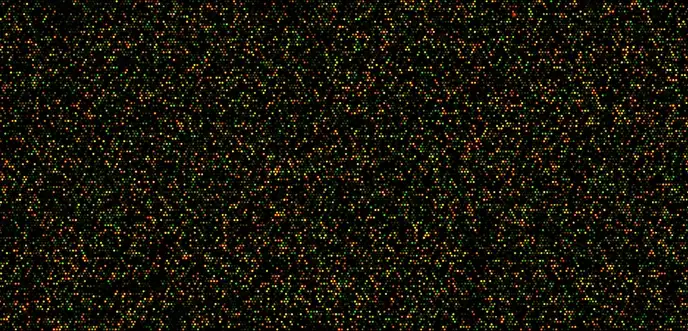

Gene expression analysis

Protein profiling

Drug discovery

Pathogen detection

Small molecule array

FAQs

Tailoring microarrays to suit specific research objectives is possible, whether it involves discovering new associations, confirming, and refining previous findings, or monitoring and surveilling known and significant variants. Crafting the optimal microarray for your research or diagnostic product doesn't have to be a daunting or time-consuming task.

To validate the quality systems, we adhere to ISO 13485, ISO 9001 certification standards, ensuring the compliance with highest standards for design, manufacture and assembly of products for laboratory use and research.

Explore our advanced technology solutions. Contact us for a free consultation.

We value long-term partnerships and work to understand your research and commercial goals. Whether you’re expanding an existing platform or exploring a novel application, we’d love to collaborate.